Step1: Define OPM organization

Navigation:

Inventory {R} àSetupàOrganizationàOrganization

Name

& location of the organization is provided and inventory organization is

defined in the organization classification.

ACCOUNTING

INFORMATION & INVENTORY INFORMATION is provided in Additional organization

information.

Above

window describes the ACCOUNTING INFORMATION

In

the Above window inventory parameters are defined. For Process Manufacturing check

box is very important, this check box should be checked only in this way a

process manufacturing enabled Inventory organization is defined. All Other

information will be the same as of other discrete organization. All other

relevant information is captured as shown in the below Screen shots

Costing

Information:

Lot

Information:

Item

Sourcing:

Inter-Org

Information

Other

Accounts Information

After

Defining all the parameters of Process Manufacturing Organization we will be

able to work in any form in Process Manufacturing Modules just by assigning

this org to a specific Application.

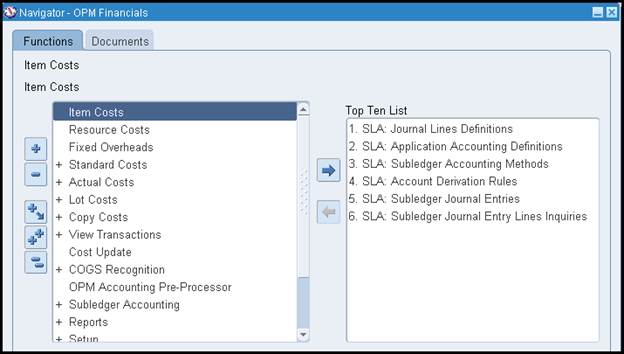

Step2: OPM Financials

Defining

Cost Types:

Navigation:

OPM financial >setup > cost types

The

subsequent paragraphs describe setting up cost types.

To

enter a cost type:

1.

Navigate to the Cost Types window.

2.

Enter the Cost Type to represent code that identifies the costing method to be

used in cost calculations. For example, enter STND for standard costing.

Required

3.

Enter a brief Description of the cost type. For example, enter Standard Costing

for the standard cost type. Required

4.

Indicate the Cost Method you are defining:

•

Standard

Cost

•

Actual

Cost

•

Lot

Cost

If

Lot Cost is selected then the Raw Material Calculation type and Product

Calculation types are not applicable and they are disabled.

Establishing

Lot Costing

Lot

costing, also known as Specific Identification Type costing, lets you calculate

and Store costs at the lot level. That is, each lot has a unique cost

associated with it and it retains this cost until the entire lot is consumed.

The lot costs are computed on a perpetual basis.

•

Lot

costing lets you store unique costs for each lot.

•

You

can track the cost of a lot from its creation through all consumptions.

Cost

Types

Usage

It

indicates if the cost method is for general or Lab use. The general usage

method is set by default. If you set the stage to general use, the cost rollup

considers only the production and costing recipes. If you set the usage to lab

use, the lab recipes are used over the production or costing recipes. The usage

field is valid only for the standard cost type. If you are using the actual

cost type, then this field is disabled.

Lot

(Actual) Cost Type

This

is only available for Lot Cost Methods. Enter a start date. The start date is

used to collect all transactions that happened after the specified date for lot

cost calculation purposes.

If

this field is left blank, then the Lot Actual Cost process uses all

transactions in the system for the OPM Company for which the Lot Actual Cost

process is run. The process then selects a large number of transactions and

could result in performance problem as large number of records are being

inserted into the lot cost tables. It is recommended that you set this field

depending on how long lots are typically held for consumption in inventory. It

could be a few inventory periods from the current period. For example, if the

current period is January 2004, then you can specify September 1st, 2003, to

ensure all transactions from the prior three inventory periods are considered.

If some of the lot costed items have lots dating further back, then specify

appropriate value.

Alternate

Cost Method

If

the cost method is an Actual Cost method, then the check box is enabled.

If

the lot cost checkbox is enabled, then the Raw Material Calculation Type and

Product Calculation Type are disabled and the Start Date and Alternate Cost

Method fields are enabled.

Both

Standard and Actual cost methods are allowed but not Lot Actual Cost methods.

Establishing Standard Costing

When

you select the standard cost calculation, you define the cost of ingredients in

each inventory organization during a specific period of time. The cost

information remains static during each defined time period. OPM Costing

calculates the standard costs of items using the Standard Cost Rollup, based on

recipes, formulas, and routings defined in the OPM Product Development

application

Standard

cost lets you define the costs for items, formulas, formula ingredients,

recipes, and resources used during the production process.

For

standard costs:

•

Establish

the formulas, routings, and recipes

•

Run

the Cost Rollup process

The

cost of a product is based on:

•

Formulas,

recipes, and routings

•

Resource

costs

•

Overheads

This

is a more dynamic method of calculating Item costs based on actual inventory

and resource transaction data. The following are the business transactions that

are used to calculate the actual costs:

•

Purchasing

receipts including Freight and Special Charges estimated on the PO, returns,

and corrections of receipts

•

Paid

Invoices

•

Batch

ingredient consumption and resource usage

•

Opening

inventory balances

•

Cost

overheads

•

Cost

adjustments

•

General

Ledger Expense allocations for indirect overheads

•

All

material transactions including internal order receipts

OPM

also captures freight and special charges on a purchase order.

Allocating

General Ledger expense is a method by which you can distribute the indirect

expenses of manufacturing (such as administrative and general expenses) to item

costs.

The

balances in the expense accounts are distributed to item(s) based on either

fixed percentages or dynamically derived using other General Ledger account

balances, for example, statistical balances that track the item quantities or

resource usages.

For

Actual Cost Methods, you can establish a variety of actual cost calculations

based on the raw material calculation type you associate with the cost method

and the production calculation type. There are 15 different possible

combinations in OPM (note the discussion for the Raw Material Calculation Type

field). With the lot cost support an Actual Cost method can be defined as a Lot

Cost method.

Updates

to the general ledger are made using the cost method defined on the Fiscal

Policy window regardless of the cost type. The description for the cost type

you specified displays automatically.

Raw

Material Calculation Type

You

can only access this field if you are defining the Actual Costing method in the

Cost Type field. Indicate the type of raw material cost calculations that will

occur for this actual costing method. The valid options are listed as follows:

- Period moving average cost (PMAC)

- Period weighted average cost (PWAC)

- Perpetual weighted average (PPAC)

- Last transaction (LSTT)

- Last invoice (LSTI)

The

type descriptions (shown in parentheses) are abbreviations for these

calculation types. The lookup displays both the calculation type and the

abbreviation. Required.

You

can only access this field if you are defining the Actual Costing method in the

Cost Type field. If you want OPM to derive actual costs for product components,

indicate the type of calculations it should perform. The valid options are

listed.

- Period moving average cost (PMAC)

- Period weighted average cost (PWAC)

- Perpetual weighted average (PPAC)

The

type descriptions (shown in parentheses) are industry standard abbreviations

for these calculation types; the lookup displays both the calculation type and

the abbreviation.

Step3: Defining Cost Calendars

You

maintain costs by defining the costing calendars. A cost calendar can be shared

across multiple cost types and legal entities. A cost calendar can span

multiple years.

OPM

financial >setup > cost calendar

For

each costing calendar, you can define an unlimited number of costing periods.

Each period is assigned a period status to indicate costing activity that is

permitted.

•

Never Opened - the period was never opened, you cannot establish costs or run

any cost processes in a never opened period.

•

Open - all activity is allowed.

•

Frozen - no updates can be made for existing items (however, new item costs can

be entered or calculated and their costs updated).

•

Closed - no activity is performed in a closed period. Periods cannot be

reopened for costing activity once they are closed.

The

costing calendar is completely separate from the fiscal calendar and the

periods therein. Cost Calendars support multiple legal entities and cost type.

You cannot assign two calendars to the same legal entity and cost type

combination for the same time period. For example, if you define a cost

calendar called FY06 - monthly calendar for the year 2006 and assign to a Legal

Entity and cost type, you cannot assign another cost calendar, Q06 - quarterly

calendar for year 2006, to the same Legal Entity and cost type combination.

If

you are using the Period Moving Average Cost, then use the same start and end

dates for the period as the fiscal financial calendar defined for your Legal

Entity's Primary Ledger in GL.

The

Cost Calendars window supports multiple languages (MLS enabled). When you call

this window, the Globe icon is enabled. If you have multiple languages

installed, then use the option to add the calendar description in any of the

installed languages.

Defining Cost Component Classes

The

unit cost of an item is usually broken down into several buckets that can be

attributed to the various sources that form the basis of the cost, for detailed

tracking and analysis purposes. Cost Component Classes are used to identify the

individual buckets or component costs that make up the total cost, for example,

direct material costs, freight costs, labor costs, production or conversion

costs and so on. Any number of cost component classes can be defined and used

to break down the item costs. The cost component classes are classified into 5

different elements or usages: Material, Resource, Overhead, Expense Allocation

and Standard Cost Adjustment types.

Costs

from several ingredients, routings, overheads, and allocations can be

summarized into one or more component classes.

OPM

financial >setup > cost component class

1.

Navigate to the Cost Component Classes window.

2.

Enter the code to identify the Component Class.

For example, enter DRYMAT for raw materials, or SOLMAT for solutions. Required

3.

Enter a Description for the component class. For

example, enter Raw Materials or Solutions. Required

4.

You have the option of building component

class association hierarchies for reference and reporting purposes. The Primary

Component Class indicates the primary cost component class with which the

component class you are defining now is associated. The default is the class

code you specified in the Component Class. You can change the entry.

5.

Component Group is an optional entry that lets you further

group the component classes for analysis and reporting purposes.

6.

Usage indicates if this cost component

classification is being entered for use as a material, overhead, resource, or

expense detail from routings. Select one of the following values (Required):

a.

Material

b.

Resource

c.

Overhead

d.

Expense

Allocations

e.

Std

Cost Adjustment

Once you set the

usage indicator for a component class, it cannot be changed after costs have

been defined using this component class.

Once costs have

been created or calculated using a component class, the usage cannot be

changed.

7.

Enter the Sort Sequence for the

component class. It indicates the order in which component classes displays on

forms and reports. 1 is the first or top line and 2 indicate the second line,

and so on. A zero (0) lets the application to determine the sort order.

Required.

8.

Product Cost Calculation indicator lets you

flag those component costs to be excluded from the Cost Rollup process. Certain

identifiable costs (for example, transfer costs) are for specific ingredient

items, and are not required to be rolled up into the products. The valid values

are:

a.

Include

in Product Cost Calculation

b.

Exclude

From Product Cost Calculation

Select

Exclude From Product Cost Calculation if this is a non-product cost component

class. The default, Include in Product Cost Calculation, applies if the

component class must be included. This flag is not applicable for Lot Cost.

9.

Valuation Option indicator lets you identify whether

the component class must be used for valuing inventory or not. The valid values

are:

a.

Will

be used for inventory valuation

b.

Will

not be used for inventory valuation

10.

The valid values for Purchase Price Variance are:

a.

Include

in Purchase Price Variance Calculation

b.

Exclude

from Purchase Price Variance Calculation

Select the Include

in Purchase Price Variance Calculation option (default), if the cost for this

component class is used in calculating the inventory valuation for purchase

price variance (PPV). Select the Exclude from Purchase Price Variance

Calculation option, if the component class must not be used in PPV calculations.

To

process indirect component for standard costing:

Overheads

Resources

1.

Navigate to the Component Classes window.

2.

Choose Standard Cost Adjustment for Usage.

3.

After completing the Cost Component Classes

window, open the Item Costs window by selecting Item Costs from the

Inquiries menu.

4.

Complete the Item Costs window. Enter the

unit cost reflecting the revision or adjustment indicated on the Cost Component

Classes window. See: Item Costs.

5.

When you add a new cost, it is recommended that you

perform a cost rollup and cost update to calculate the revised unit cost and

process the GL financial cost, respectively. See: Cost Rollup and Cost Update.

Indirect

Component Processing for Standard Costing

When

standard costs are used, you can update adjustments or indirect components of

standard product costs separately without defining formula routings and/or

overhead details. You can identify the standard indirect cost component, update

non-direct materials and resources within production batches, and reconcile

"batch close" variance at the close of a production batch.

Defining Cost Analysis Codes

An

individual component cost identified by a particular cost component class can

be further broken down using cost analysis codes for more granular tracking of

costs. The cost analysis codes are used to group component costs from multiple

cost component class types to provide an alternate view of the total cost. For

example, you can define direct or indirect analysis codes for each cost

component

OPM

financial >setup > analysis codes

1.

Navigate to the Cost Analysis Code window.

2.

Enter the Code to identify the cost analysis

type. For example, DIR for Direct Costs, or IND for Indirect Costs. Required

3.

Enter a Description for the analysis code. For

example, enter Value Added or Non-value Added. Required

Defining Fiscal Policies

The

Fiscal Policy options define the Legal Entity-wide parameters that determine

the cost type that will be used for inventory valuation, the default material

and overhead cost components and analysis codes for actual cost processing,

additional cost types used for costing simulations

Following

are the procedures to establish fiscal policy options. The "Event Fiscal

Policies" and "Assign Additional Ledger Valuation Methods"

topics provide more details on setting up additional details for a Legal

Entity.

OPM

financial >setup> lot cost >Fiscal policy

1.

Navigate to the Fiscal Policies window.

2.

Enter the Legal Entity name for which you are

defining fiscal policy options. Require

3.

Enter the name of the default Ledger for this

fiscal policy company.

4.

Displays the Base Currency code for this

company.

5.

Enter the cost type to use for inventory valuation in Valuation

Method.

6.

Indicate if the fiscal policy is based on costs from

the previous cost period or the current period in Cost Basis.

Default

Material Component

7.

Enter the default material component that identifies

the cost component to be applied to the fiscal policy in Component Class.

Required

8.

Enter the code that identifies the cost Analysis

Code to be applied to the fiscal policy

Default

Overhead Component:

1.

Enter the default overhead component that identifies

the cost component to be applied to the fiscal policy in Component Class.

Required

2.

Enter the default overhead Analysis Code that

identifies the cost analysis code to be applied to the fiscal policy

NOTE: Till up to now we

have made OPM org and defined the related and necessary setup in OPM

Financials. Now we shall proceed to product development Where we will be

able to incorporate formulas, routings and recipes.

Setting up Parameters

Set

up Oracle Process Manufacturing (OPM) Product Development parameters in the

Product Development Security Manager responsibility. You can set up parameters

for new organizations, or query and modify parameters for existing

organizations.

Parameter

values can vary by organization. These parameters control various functions in

the Product Development application. For example, if version control for

formulas is enabled for organization PR1, then at the point of saving a

formula, the application checks the formula organization to determine whether

or not to apply version control rules. Organization PR2 can have a different

setting for formula version control.

Product

development security manger > Organization parameter

1. Navigate to the Product

Development Parameters window.

2. Enter Organization

as the context inventory organization.

3. Organization Type is:

a.

Plant

for a manufacturing facility.

b.

Laboratory for a research or lab facility.

NOTE: First of all these

parameters are set for all the organizations then these are defined for

individual OPM orgs. As shown in the below screen shots

Formula

1. Enter Allow Zero

Ingredient Quantity as:

a.

No to specify you cannot enter ingredients with zero

quantity. An error displays when a zero ingredient quantity is entered. Default

b.

Yes to specify possible entry of a zero

ingredient quantity.

c.

Allow with warning to specify entry of a zero

ingredient quantity with a warning message displayed. If you accept the

warning, then you can proceed.

2. Enter Byproduct

Active as:

a.

Yes to specify you can access the By-Products

window. Default.

b.

No to specify you cannot access the By-Products window

3. Enter Default

Consumption/Yield Type as:

a.

Automatic By Step for automatic consumption of

ingredients and automatic yield of products and byproducts as each step is

completed. Default

b.

Manual for ingredients to default to manual

consumption and inserted products and byproducts to default to manual yield.

c.

Incremental for inserted items to default to

incremental consumption or incremental yield.

4. Enter Default

Formula Status as:

a.

New to make changes at any time, assuming you

have security access. Default.

b.

Approved for Laboratory Use for use in

laboratory batches and cost rollups for the laboratory.

c.

Approved for General Use for use in

production batches.

d.

On Hold to specify the object cannot be used until

the status is changed.

e.

Frozen to prevent any further changes to the

object and any dependent data.

f.

Obsolete/Archived to specify the object can no longer

be used unless the status is changed.

5. Enter Formula

Security for Lot Genealogy as:

a.

No to specify formula security rules are not enforced in

lot genealogy. Default.

b.

Yes to specify formula security rules are

enforced in lot genealogy.

6. Enter Mass UOM as:

a.

MASS to specify use of the mass unit of measure

type when item quantities are converted to a common unit of measure for

scaling, theoretical yield, and total output quantity. Default

b.

Another

valid unit of measure type for conversion purposes. Set up this unit of measure

type.

7. Enter Material

Release Type as:

a.

Automatic when ingredients quantities are consumed

automatically.

b.

Manual when ingredient quantities are consumed

manually.

c.

Incremental when ingredient quantities are backflushed

by incremental backflushing.

d.

Automatic by Step when ingredient quantities are

consumed automatically as the step is released.

8. Enter Version

Control as:

a.

No to specify version control is not active for formulas.

Changes can be made to an existing formula without the need to change its

version. Default

b.

Yes to specify full version control is active

for formulas. Changes made to a formula require a new version. This excludes

changes to formula status, mark for purge, and the Undelete functionality.

c.

Optional to specify version control is discretionary

for formulas. You can create a new version when you update an existing version.

9. 12. Enter Volume

UOM as:

a.

VOL to specify use of the volume unit of

measure type when item quantities are converted to a common unit of measure for

scaling, theoretical yield, and total output quantity.

b.

Another

valid unit of measure type for conversion purposes. Set up this unit of measure

type.

10. 13. Enter Yield UOM as:

a.

MASS to specify use of the mass unit of measure

type when item quantities are converted to a common unit of measure for

scaling, theoretical yield, and total output quantity. Default

b.

VOL to specify use of the volume unit of

measure type when item quantities are converted to a common unit of measure for

scaling, theoretical yield, and total output quantity.

c.

Another

valid unit of measure type for conversion purposes. Set up this unit of measure

type.

NOTE: Same

will be incorporated for OPM orgs separately as shown in the following Screen

Shot, however here the check boxes of plant and Laboratory should be checked

Operation

1. Enter Default

Operation Status as:

a.

New to make changes at any time, assuming you

have security access. Default.

b.

Approved for Laboratory Use for use in

laboratory batches and cost rollups for the laboratory.

c.

Approved for General Use for use in

production batches.

d.

On Hold to specify the object cannot be used until

the status is changed.

e.

Frozen to prevent any further changes to the

object and any dependent data.

f.

Obsolete/Archived to specify the object can no longer

be used unless the status is changed.

2. 15. Enter Version

Control as:

a.

No to specify version control is not active for

operations. Changes can be made to an existing operation without the need to

change its version. Default

b.

Yes to specify full version control is active

for operations. Changes made to an operation require a new version. This

excludes changes to operation status, mark for purge, and the Undelete

functionality.

c.

Optional to specify version control is discretionary

for operations. You can create a new version when you update an existing

version.

NOTE: Same

will be Defined for Separate OPM orgs as shown below

Routing

1. Enter Default

Routing Status as:

a.

New to make changes at any time, assuming you

have security access. Default.

b.

Approved for Laboratory Use for use in

laboratory batches and cost rollups for the laboratory.

c.

Approved for General Use for use in

production batches.

d.

On Hold to specify the object cannot be used until

the status is changed.

e.

Frozen to prevent any further changes to the

object and any dependent data.

f.

Obsolete/Archived to specify the object can no longer

be used unless the status is changed.

2. Enter Step

Release Type as:

a.

Automatic to indicate that the step is automatically

released or completed when subsequent steps are released or completed.

b.

Manual to indicate that the step is released

manually.

3. Enter Enforce

Step Dependency as:

a.

No to specify step dependency is not enforced. Default.

b.

Yes to specify step dependency is enforced.

4. Enter Version

Control as:

a.

No to specify version control is not active for routings.

Changes can be made to an existing routing without the need to change its

version. Default

b.

Yes to specify full version control is active

for routings. Changes made to the routing header or organization specific

details require a new version.

c.

Optional to specify version control is discretionary

for routings. You can create a new version when you update an existing version.

NOTE: Same will be applied for other

OPM Orgs separately as shown below

Recipe

1.

Enter

Default Recipe Status and Default Validity Rule Status as

follows:

a.

New to make changes at any time, assuming you

have security access. Default.

b.

Approved for Laboratory Use for use in

laboratory batches and cost rollups for the laboratory.

c.

Approved for General Use for use in

production batches.

d.

On Hold to specify the object cannot be used until

the status is changed.

e.

Frozen to prevent any further changes to the

object and any dependent data.

f.

Obsolete/Archived

to specify the object can no longer be used unless the status is changed.

2.

Enter Process Instruction Paragraph as:

a.

NULL

if the process instruction paragraph is not used. Default.

b.

A

user-defined paragraph code to define process instruction entry using the

standard Text Editor functionality. Process instructions entered in the Recipe

Designer are stored against this paragraph code.

3.

Enter Recipe Type as:

a.

Master to indicate that the default recipe type is

process cell specific. Master recipes define exactly how a product is made in a

specific process manufacturing cell.

b.

Site to indicate that the default recipe type is

at the site level. There is one site recipe for each site that makes the

product, or some portion of the product. A site recipe has the same structure

as a general recipe, but may be modified for the local language and unit of

measure. It may also be modified to take into account local material

availability, or it may only define a part of the general recipe that is

actually performed on the site.

c.

General

to indicate that the default recipe type is one general recipe for each

specific product variation made by a company. It defines, in equipment

independent manner, the material and process dependencies required to make a

product. The general recipe is usually created during or after the pilot plant

scale up of a research and development recipe.

4.

Enter Version Control as:

a.

No to specify version control is not active for recipes.

Changes can be made to an existing recipe without the need to change its

version. Default

b.

Yes to specify full version control is active

for recipes. Changes made to the recipe header or organization specific details

require a new version. This excludes changes to alidity rules, step material

association, recipe step quantities, customers, recipe status, mark for purge,

and the Undelete functionality.

c.

Optional to specify version control is discretionary

for recipes. You can create a new version when you update an existing version.

NOTE: Same will be defined for other

OPM orgs as Shown below

Substitution

1. Enter Default

Substitution Status as:

a.

New to make changes at any time, assuming you

has security access. Default.

b.

Approved for Laboratory Use for use in

laboratory batches and cost rollups for the laboratory.

c.

Approved for General Use for use in

production batches.

d.

On Hold to specify the object cannot be used until

the status is changed.

e.

Frozen to prevent any further changes to the

object and any dependent data.

f.

Obsolete/Archived to specify the object can no longer

be used unless the status is changed.

2. Enter Version

Control as:

a.

No to specify version control is not active for recipes.

Changes can be made to an existing substitution list without the need to change

its version. Default

b.

Yes to specify full version control is active

for substitution lists. Changes made to the item substitution list or

organization specific details require a new version. This excludes changes to

status, mark for purge, and the Undelete functionality.

c.

Optional to specify version control is discretionary

for substitution lists. You can create a new version when you update an

existing version.

Laboratory

Enter

Costing Source Organization as the default organization for least-cost

formulation. All process-enabled inventory organizations are available.

Above

check will protect the data table visibility at back end. Formula data is

visible only in TOAD when this box is check.

OPM-

PRODUCT DEVELOPMENT

ATTENTION:

After

Deploying all above necessary setup we will be able to incorporate the Formula,

Operations, Routing and Recipe. Screen shots of the user related application is

as follows. These are self explanatory so there is no need to explain all

these. However these are fully explained in the Product development User guides

Formulator

> Setup > Formula Class

Formula

Classes group formulas with similar characteristics and requirements for

reporting purposes. For example, use a formula class to classify all formulas

for ACRYLIC paints, or to classify all formulas for ORGANIC paints. Food

seasoning formulas could be grouped under a SEASONINGS class. You specify the

formula class on the Formula Details window.

Formulator

> Setup > Status Codes

Enter

a new Status Code number. The number you enter is sorted into ascending

order with the other status codes when you save and reopen the Status Codes

window.

Codes

entered between any two predefined codes, such as 101 to 199, or 201 to 299 are

included in the workflow associated with the predefined status code with the

same first digit. For example, if you enter the code 110, it becomes part of

the workflow associated to Code 100. If you enter a code number 699, it becomes

part of the workflow associated to Code 600. Predefined status codes are shown

in a table at the end of this task.

The Enable

Version check box determines whether the status code entered is set up for

version control. Any modification made to an operation, routing, formula, or

recipe while it is set to the status entered in the Meaning field initiates or

bypasses activation of a new version depending on the selection you make here,

and the value entered for the appropriate version control profile option.

- Select the check box if you want the status code to

enable version control when a modification is made to an operation,

routing, formula, or recipe. The appropriate version control profile

option must be set to Yes or Optional.

- Clear the check box if you want the status code to

bypass version control when a modification is made to an operation,

routing, formula, or recipe.

Status

Details

The

Status Details window enables you to enter a target status for a new status

code. You can optionally enter rework status, pending status, and assign a

workflow indicator.

To

enter status details:

- Enter a Target Status for the new Status Code.

This is the code that appears as the destination status on the Change

Status window. You have the ability to enter several Target Status

destinations for each Status Code. They must be entered on separate lines.

Required.

- Optionally, enter a Rework Status for the new

Status Code. The Rework Status code defines the destination for the listed

Status Code when it is not accepted and must be reworked.

- Optionally, enter a Pending Status for the new

Status Code. The Pending Status code defines a destination of the listed

Status Code when it enters the approval workflow and is pending approval.

- Select one of the following as Workflow Indicator:

- Enable or Disable Workflow to indicate that the fields listed in the row enable

or disable the workflow.

- Workflow Approval

to indicate that the fields listed in the row require workflow approval.

- No Workflow Approval

to indicate that the fields listed in the row do not require workflow

approval.

Formulator

> Setup > Recipe Generation

Formula

Details

Formula

Details: Products

Ingredients

Ingredients:

Operation

Details

Operations

are a combination of one or more activities performed in a production batch and

the resources used to perform those activities. The Operation Details

Activities window links operations to activities. Use the Activity Factor and

activity-resource association to enter an activity several times within an

operation. Activity Factor simplifies data entry of the same activity several

times by defining the specific number of times that an activity is performed

during an operation. Activity factor is taken into consideration for planning

and resource calculation purposes. Display the Operation Activity window to

link one or more resources to a single activity. Go to the Operation Activity

Line Edit window to edit individual activity lines.

Understanding Sequence Dependent

Operations

Sequence

dependency indicates that there is an additional setup time required when

products are processed through each operation in a specific sequence.

Enter

an Activity required for this Operation. A Description of this

activity displays.

Enter

the Activity Factor to specify the number of times the activity is

performed in this Operation.

For example, if a

quality test must be performed at the beginning, middle, and end of a mixing

time period, rather than defining the activity and associated resources three

times, use the Activity Factor or multiplier to indicate the number of

iterations for the same activity.

Sequence

Dependency

is selected when the activity has a sequence dependent setup. It is cleared

when there is no sequence dependency.

Enter

the Offset Interval as the time delay from the start of the activity to

the point where the resource is actually required.

Activity-Resource

Details

The

Operation Activity window assigns resources to each activity, and lets you edit

a resource line once activities are associated with an operation. You access

this window when you click Resources on the Operation Details Activities

window.

Charge

calculates resource usage by capturing the number of passes required to process

a step. This is based on the maximum capacity of the step as derived from

specific resources used.

Throughput

Process

units of measure and usage units of measure are derived from the plant resource

if one is defined. You can override these values using this window. A process

quantity is converted to an operation process quantity unit of measure if

needed.

Process

Quantity

This

value combined with the Usage quantity defines the usage rate. For example, if

a resource can mix 200 gallons per hour, enter 200 as the Process Quantity, 1

as the Usage, and the unit of measure for hours.

Scheduling

Information

- Select Auxiliary for resources that work as

companions with the primary resources to perform an activity in the

Operation. These resources do not affect the rate of the Operation. For

example, a primary resource in a mixing activity is a mixer with a

throughput rate of 100 gallons per hour. An auxiliary resource is the

worker who operates the mixer. No matter how fast or slow the worker is,

the mixer rate remains at a constant 100 gallons per hour.

- Select Primary to indicate that this is the

rate determining resource. It limits or determines throughput. It is also

referred to as the bottleneck or critical resource. There can only be one

Primary per resource.

- Select Secondary to indicate the resource that

would replace the primary resource when it is not available. This

resource performs the same task as the primary resource. It is

unconstrained, and it has usage. The Advanced Planning and Scheduling

application does not schedule the secondary resource.

Enter

the Count as the number of resources needed for the activity entered.

For example, it two blenders are used for mixing, enter a 2 in the count.

Enter

the Offset Interval as the time delay from the start of the activity to

the point where the resource is actually required.

Scale

Type

- Select Proportional Scaling if the resources

change in a ratio that is proportional to the quantity of material being

processed.

- Select Fixed if the resources do not change,

regardless of the quantity of material being processed.

- Select Fixed By Charge if the resources change

as a result of the number of charges specified.

Operation

Resource Process Parameters

Process

parameters are a component of the process instructions necessary to run

resources during the batch process. They are usually machines or instruments

and are the standard for executing a task. They can be generic or specific.

Each industry and company uses different machines and instruments, and there

are different requirements for recording process parameters.

A

process parameter details information such as temperature, pressure, or time

that is pertinent to the product, but does not fall into the classification of

input or output. You can use process parameters as set points, comparison

values, or in conditional logic.

The following

fields default from the process parameter set up in the planning application:

- Seq

is the sequence of the resource process parameter.

- Parameter

is the process parameter name. For example, Bath Temperature.

- Minimum

is the lowest acceptable value for a numeric range type of process

parameter.

- Maximum

is the highest acceptable value for a numeric range type of process

parameter.

- Units

is the unit of measure for the process parameter.

You

can override certain process parameters at the operation and recipe levels. Click

Reset Values to remove overrides set up for a process parameter. The following

illustrates how the process parameter is reset.

The

hierarchy is:

- Recipe

- Operation

- Default value from the planning application

For

example, if the default for a process parameter from the planning application

is set to 10, you can override it at the operation level and at the recipe

level. The following values are used for illustration:

- Recipe = 20

- Operation = 15

- Default value from the planning application = 10

If

you click Reset Values for the process parameter on the:

- Recipe Details window, then the process parameter value

changes from 20 to 15, the next step down in the hierarchy.

- Operation Activity Details window, then the process

parameter value changes from 15 to 10.

If no

override exists at the operation level, and you click Reset Values at the

recipe level, then the process parameter value changes to 10, which is the

original default value from the planning application.

Routing

Details

The

Routing Details window enables you to enter the details for a specific routing.

Understanding

the Enforce Step Dependency Indicator

When

Enforce Step Dependency is selected, several business rules are applied:

- The Release Type field is set to Manual to indicate

that the step must be released and completed manually.

- You cannot change the step dependency and step release

type at the step level.

- All steps must be completed before you can complete a

batch using this routing.

- All steps must be closed before you can close a batch

using this routing.

- Business rules validate step start and completion dates

and times for appropriate batch step rescheduling.

Routing

details:

- Navigate to the Routing Details window.

- Enter the code for the Routing. Required.

- Enter a Routing Version of the Routing.

Required.

- After entering all relevant information and saving the

Routing with the default Status of New, return to this window if

you need to change Routing Status by selecting Change Status from

the Actions menu. Depending on whether Workflow is enabled, a

different set of statuses is available.

Select a Status

for the Routing you are entering from one of the following:

- Approved for Laboratory Use to indicate that the Routing is approved for

laboratory use.

- Approved for General Use to indicate that the Routing is approved for use in

production.

- Obsolete/Archived

to indicate that the Routing is no longer approved for use and is

obsolete, archived, or both.

If Workflow is

enabled, when you select:

- Approved for Laboratory Use, Status changes to Request Approval for Laboratory

Use until all approvers have accepted the Routing, at which time its

Status changes to Approved for Laboratory Use.

- Approval for General Use, Status changes to Request Approval for General Use

until all approvers have accepted the Routing, at which time its Status

changes to Approved for General Use.

Refer to the

Understanding the "Status Approval Workflow" topic for additional

information.

- Enter a Routing Description that briefly

describes the Routing. Required.

- Enter a Class for the Routing to identify how it

is categorized. The Class Description assigned to the Class

displays.

- Enter the Valid From date for this Routing. The

default date is the current system date. Required.

- Enter a To date for the expiration of this

Routing. If there is no expiration date for this Routing, leave the field

blank.

- Enter the process Quantity for this Routing.

This is the total quantity of material for the Routing, and is used to

scale individual step requirements. Required.

- Enter the process Quantity UOM associated with

this Routing. The process Quantity UOM must interconvert with the UOM

defined for Theoretical Process Loss based on the primary product UOM

conversion in the Routing. Required.

- Enter the Planned Loss for this Routing.

This value is expressed as a percent. For example, a loss of 1.304% would

be entered as 1.304.

- The Theoretical Process Loss for this Routing

displays. This value is entered on the Theoretical Process Loss window,

and is based on the value assigned to the Class associated with this

Routing.

- Enter the Owner to indicate the individual who

is responsible for initiating this Routing. Required.

- Enter the Owner Organization to indicate the

plant, laboratory, or other facility that is responsible for initiating

this Routing. Required.

- Enforce Step Dependency is:

- Selected when the routing enforces step dependency.

- Cleared when the routing does not enforce step

dependency.

Routing

Steps

- Enter the Step number to associate with an

Operation in this Routing. It is recommended that the first number in this

sequence be 10, the second 20, and so forth. This enables you to add

intermediate steps between 10 and 20 at a later time. Required.

- Enter the code for the Operation performed in

this Routing. Required.

- Enter a Version number for the Routing.

Required.

- The Description of the Operation entered

displays.

- Enter the Operation Step Quantity as the

quantity of material associated with this Step. The UOM for the

Step Quantity displays.

- Min Transfer Qty

is for future use by the Oracle Advanced Planning and Scheduling

application. It is intended to reduce overall lead times by defining the

minimum amount of material that must be produced in a step at a specific

production operation and resource before the next operation can begin.

This reduces bottlenecks by letting processes transfer an interim quantity

of completed material to the next step without the requirement to complete

the entire step.

- Select the Release Type to indicate how the step

is released as:

- Automatic

if the step is automatically released or completed when subsequent steps

are released or completed.

- Manual

if the step must be released and completed manually.

All steps are

completed if the batch is completed, regardless of the step release type.

- Save the window.

- Optionally, click Step Dependencies to display

the Routing Step Dependencies window.

- Optionally, click Edit Operation to display the Operation

Details Activities window.

- Optionally, click Edit Step Line to display Routing

Step Line window.

To

mark the routing for deletion:

- Choose Mark for Purge from the Actions

menu.

- The record is marked for deletion.

- Save the window.

To

edit the routing text:

- Choose Edit Text from the Actions menu.

- Make the appropriate edits to routing text.

- Save the window.

To

display the Specifications window:

- Choose Specifications from the Actions

menu. The Specifications window displays.

- Evaluate specifications.

- Close the window.

To

display the Samples window:

- Choose Samples from the Actions menu. The

Samples window displays.

- Evaluate the samples.

- Close the window.

To

change the routing status:

- Choose Change Status from the Actions menu.

- Change the Current Status displayed by selecting

a different Status from the Change Status To list.

- Click OK.

- The Routing Details window displays the revised Status

for the routing.

To

generate step dependencies:

- Position the cursor in the routing header.

- Choose Generate Step Dependencies from the Actions

menu. A message displays to indicate that the dependencies have been

generated.

- Click OK.

- Select the dependent Step.

- Click Routing Step Dependencies. The Routing

Step Dependencies window displays. Enter data as described in the

"Entering Routing Step Dependencies" topic.

To

duplicate a record:

- Query the Routing Details record you want to

duplicate.

- Choose New from the File menu.

- Choose Duplicate Record Above from the Edit

menu.

- Enter a new Routing name and Version

number.

- Save the window.

Routing

Step Dependencies

The

Routing Step Dependencies window enables you to create and modify the

interrelationships between routing steps. Step dependencies are those

relationships between routing steps that establish whether a specific step can

or cannot start until another step is completed. Routing Step Dependencies

reduce the routing development time by establishing a default sequence for

operation steps during a production run. Step dependencies are implemented at the

routing maintenance level to enable automatic step quantity calculation in

recipes.

You

are able to define new dependencies or delete the ones you do not want. For

example, if step 10 is BAKING and step 20 is the COOLING step, then step 10

must be completed before step 20 can begin. By this definition, step 20 is

dependent on the completion of step 10. Step dependencies are used to calculate

planned start times however, they can be overwritten.

Any

previous step must be validated against any routing currently being edited, and

it must not be the same as the current step. Avoid defining circular

references, for example Step 10 is less than Step 20 is less than Step 10.

Step

Dependencies are definable as:

- Finish-to-start with no offset, to indicate that a

process step begins immediately after the completion of its preceding

step. For example, a consecutive addition of ingredients is required

without interruption.

- Finish-to-start with positive offset, to indicate that

a process step begins a specified period of time after the completion of

its preceding step. For example, time is required to rest material before

the addition of another ingredient.

- Finish-to-start with negative offset, to indicate that

a process step begins a specified period of time before the completion of

its preceding step. For example, a production device needs to be activated

before the addition of the next ingredient.

- Start-to-start with no offset, to indicate that a

process step begins at the same time as the step it depends on. For

example, there is a need for simultaneous addition of ingredients without

interruption.

- Start-to-start with positive offset, to indicate that a

process step begins a specified time after the beginning of its preceding

step. This is similar to finish-to-start with negative offset, but by

specifying that the dependency is start-to-start, you can ensure the

positive offset is maintained if the previous dependent step finishes

early.

The

offset is defined in the Standard Delay field as a positive or negative number.

The application uses step dependencies when individual steps are rescheduled.

Recipe

Details

The

Recipe Details window enables you to enter the details for a specific recipe. A

Plant or a Laboratory can be associated with all the materials and resources

required to make a product at the recipe level. One or more customers can be

associated to the recipe for informational purposes.

·

Optionally,

enter and save operations.

·

Optionally,

enter and save routings.

·

Enter

and save formulas.

·

Set

up the default Organization.

·

Set

up the GMA: Default Organization profile option.

Understanding

Step Quantity Calculations

When

you select the calculate Step Qty indicator on the Recipe Details window, the

application checks to determine if there are proper step quantity material

associations. You must use a routing. Step and material associations must be

made. If any of these associations are defective, then you receive an error

message. When you use the Automatic Step Quantity Calculation, it checks

quantities in each step to verify that material is available to pass into and

out of each step. The quantity of material for a particular step is dependent

on the quantity of material that passes into or out of it. The input material

can be either the ingredient that is injected directly into the step, or it can

be the output of preceding steps. Output is represented typically by

co-products or byproducts.

- Navigate to the Recipe Details window.

- Enter the code for the Recipe to be entered.

- Enter a Version of the Recipe.

- Enter a Description for the Recipe.

- After entering all relevant information and saving the

Recipe with the default Status of New, return to this window if you

need to change Recipe Status by selecting Change Status from the Actions

menu. Depending on whether Workflow is enabled, a different set of

statuses is available.

Select a Status

for the Recipe you are entering from one of the following:

- Approved for Laboratory Use to indicate that the Recipe is approved for

laboratory use.

- Approved for General Use to indicate that the Recipe is approved for use in

production.

- Obsolete/Archived

to indicate that the Recipe is no longer approved for use and is

obsolete, archived, or both.

If Workflow is

enabled, when you select:

- Approved for Laboratory Use, then Status changes to Request Approval for Laboratory

Use until all approvers have accepted the Recipe, then its Status

changes to Approved for Laboratory Use.

- Approval for General Use, then Status changes to Request Approval for General

Use until all approvers have accepted the Recipe, then its Status

changes to Approved for General Use.

Recipe status

cannot be changed to an approved status if the formula and routing are not yet

approved. For example, the formula and routing must be approved for General Use

before the recipe status can be changed to Approved for General Use. If you

change the status of a recipe to Obsolete, Archived, On-hold, or Frozen,

validity rules associated to that recipe change to that status.

You can change the

status of recipes or validity rules to On-hold or Obsolete even if they are

used in batches as long all these batches are closed or cancelled.

- Enter the main Product for the Formula

associated with this Recipe. If you enter a new Recipe, enter the Formula

to fill this field automatically.

- The Output Quantity displays the sum of all

materials. UOM indicates the unit of measure for the Formula

associated with this Recipe.

- Enter the Formula number for the Recipe.

Required. Once a recipe is saved, this field cannot be edited. You cannot

use an inactive Formula in a recipe. The formula Version displays.

Required.

- Creation Organization

displays the organization code for the initial Owner. This field is not

updateable for an existing Recipe. Required.

- Enter a Routing number for the Recipe. A routing

can be added to an existing Recipe. The Version for the Routing

entered displays.

- Theoretical Process Loss displays the hypothetical loss of process material

associated to a routing as a percentage. If no routing is associated to a

recipe, or if no routing class is associated to a given routing, and no

Process Loss is defined for that routing, this field is blank.

- Enter the Planned Process Loss as the loss of

process material observed during production of a batch using the recipe.

If no value is entered in this field, it defaults to the Theoretical

Process Loss. You can change this value on a New or existing recipe.

- Total Output Qty displays

with its UOM.

- Enter the Laboratory that has current ownership

of the recipe. This is a Folder field.

- Enter the Owner Organization. This field is the

default organization for the Owner of the Recipe. In order for you to

enter or edit information for the Recipe, you must have an association

with this organization and permission to access and change this field.

Required.

- Enter the Owner of the Recipe. The Owner name

must be a valid User name. This field defaults to the current User.

Required.

Note: You must enter all

information on this window before you select the Calculate Step Qty check box.

- The Calculate Step Qty check box indicates

whether you want to enter step quantities manually or have the application

calculate them for you.

- Select the Calculate Step Qty check box to

enable the application to calculate step quantities automatically.

Quantities are based on the amount of materials that go into and out of

each supported step. Step Quantity fields cannot be entered after you

select the check box. You must associate all items marked as contributing

to step quantity to specific Steps on the Recipe Step/Material

Association window.

- Clear the Calculate Step Qty indicator to enter

step quantities manually. Step quantities are calculated using routing

step quantity, total output quantity of formula, and routing header

quantity.

- The following fields are display only:

- Organization

displays the Organization code that the Process Loss is being defined

for. This must be a plant or a laboratory. Required.

- Organization Name

displays a description of the plant or laboratory.

- Type

indicates whether this is a plant or a laboratory.

- Process Loss

displays the material that is lost through the process. This field is

blank if you did not enter a Routing. This field allows you to override

the default Process Loss.

- Enter the Customer number. Required.

- Name

indicates the name of the Customer associated with the Customer number

entered.

If a

routing has not been entered, this region is not available. If you calculate

step quantities in the Automatic Step Quantity Calculation, the Step Material

Associations need to be entered.

- Step

indicates the step number associated with the listed Operation in the

displayed Routing. Steps cannot be added or deleted here. However, if a

step is deleted in the base routing used for this Recipe, and the Step

field is overwritten, you must choose Delete from the Edit

menu to delete the orphaned Step. Charges are calculated for each Step

displayed. You can associate text with each Step.

- Operation

displays the operation associated with the Step. The operation Version

and Description are displayed.

- Step Quantity

indicates the default quantity of material associated with the Step. The UOM

for the Step Quantity displays. You can enter a new value in the Step

Quantity field if you do not use the Automatic Step Quantity Calculation.

If Automatic Step Quantity Calculation is used, this field is not

enterable. Required if the Step is associated to material, and you are not

using Automatic Step Quantity Calculation. Required.

- Charges

displays the total calculated charges for the step. Charges are the number

of times the Operation must be performed to complete the Step for the

specified Step Quantity. For example, a mixer that holds 50 kg would

require two charges to process 100 kg of material. Charges are calculated

from the smallest minimum capacity for all resources in the Step.

- Optionally, click Organization Details to

display the Recipe Organization Details window.

- Optionally, click Validity Rules to display the Recipe

Validity Rules window.

- Optionally, click Step/Material Association to

display the Recipe Step/Material Association window.

- Save the window.

- Choose Mark for Purge from the Actions

menu.

- The record is marked for deletion.

- Save the window.

- Select the Recipe to copy.

- Choose Copy from the Edit menu. Copying a

recipe creates a new recipe. All header fields in the the new recipe are

editable. You must change the recipe number or recipe version in the

copied recipe before saving it. Duplicate recipe names are not allowed.

The current Owner and Organization are assigned to the new recipe. Recipes

that have been marked for deletion cannot be copied.

- Click OK.

- Choose Edit Text from the Actions menu.

- Enter appropriate text.

- Save the window.

You

can duplicate a recipe, routing, and validity rules from an existing record. If

you change the routing end date prior to saving the record, then the

application checks the routing end date against the validity rule end date. If

the validity rule end date is greater than the routing end date, or blank, then

the application assigns the value of the routing end date to the validity rule

end date.

- Query the Recipe Details record to duplicate.

- Choose New from the File menu.

- Choose Duplicate Record Above from the Edit

menu.

- Enter a new Recipe name and Version

number.

- Save the window.

To

display the Formula Details window:

- Choose Formula from the Actions menu. The

Formula Details window displays.

- Close the window.

To

display the Routing Details window:

- Choose Routing from the Actions menu. The

Routing Details window displays.

- Close the window.

To

display the E-Record Details window:

- Choose E-Record Details from the Actions

menu. The E-Record Generic Query displays if this option is

implemented in your application.

- Refer to "Appendix D Oracle E-Records Events in

Product Development" for information on e-records.

- Close the window.

To

display the Specifications window:

- Choose Specifications from the Actions

menu. The Specifications window displays.

- Evaluate specifications.

- Close the window.

To

display the Samples window:

- Choose Samples from the Actions menu. The

Samples window displays.

- Evaluate the samples.

- Close the window.

Recipe

Step/Material Association

The

Recipe Step/Material Association window displays all items from the recipe

formula and lets you associate these items with specific routing steps.

Minimum

Transfer Quantity (MTQ) has a restriction on the gap between the time that the

MTQ is yielded for the item, and the start of the next routing that involves

that item. The gap is defined with a minimum and maximum value based in the

TIME unit of measure for hour. When calculating the gap, the minimum value

creates the gap, and the maximum value limits the duration of the gap between

the routing and the MTQ yield point. This MTQ calculation can be added for all

products of a recipe.

Minimum

and maximum values are optional, and blank values represent an infinite gap

between the manufacturing processes:

- If you enter the minimum value only, then a specific

gap must exist between the MTQ time point and the next routing for the

item. However, the end of the gap is infinite.

- If you enter both minimum and maximum values, then the

gap is fixed and requires the next routing to start in the defined period

after the MTQ time point.

Minimum

delay and maximum delay represent this gap. The values for these can never be

negative, and the minimum must always be less than or equal to the maximum

value. The entry of an MTQ for any of the products is not required. Blank value

for MTQ implies the full quantity must be yielded before the next routing can

start.

·

Enter

and save recipes.

·

If

the Automatic Step Quantity Calculation is used:

A routing must be

associated with the recipe.

Each item marked as

contributing to step quantity must be associated with a step, and have a conversion

specified between the standard mass unit of measure and standard volume unit of

measure.

·

All

operations must use a mass or volume unit of measure.

- Navigate to the Recipe Step/Material Association

window.

- The following fields are display only:

- Formula

displays the formula used in a recipe with the Version and Formula

Description.

- Routing

displays the routing used in a recipe with the Version and Routing

Description.

- Step

displays the step number associated with the listed Operation in the

displayed Routing. You cannot add a Step to a routing on this window. You

must do this on the Routing Details window. Required.

- Maximum Delay displays the delay offset in hours. This

is a restriction on the gap between the point in time that the minimum

transfer quantity is yielded for the item and the start of the next

routing involving the item. If the maximum delay is set, then the

material must be used before this delay. For future use by the Oracle

Advanced Supply Chain Planning application.

- Minimum Delay displays the Minimum Delay offset in

hours. This must be less than or equal to the Maximum Delay. For future

use by APS.

- Item Description

displays the descriptions each product, byproduct, or ingredient listed.

- Line Unit of Measure

displays the unit of measure for each product, byproduct, or ingredient

listed.

- Minimum Transfer Quantity displays the minimum quantity of product needed to

yield a partial quantity before the next routing can start. For future

use by APS.

- Operation

displays the operation associated with the Step. The operation Version

displays.

- Step Qty

displays the default quantity of material associated with the Step. The UOM

for the Step Quantity displays.

- Line

displays the line number for each product, byproduct, or ingredient

listed. Required.

- Item

displays the code associated with each product, byproduct, or ingredient

listed.

- Type

displays the type of Line associated in the Step as a product, byproduct,

or ingredient.

- Item Qty

displays the Quantity of product, byproduct, or ingredient yielded by the

listed Formula.

- Line UOM

displays the unit of measure for the Item Quantity.

- Close the window.

- Enter the Step from the LOV. Required.

- The following fields are display only:

- Operation

displays the operation associated with the Step. The operation Version

is displayed.

- Step Qty

displays the default quantity of material associated with the Step. The UOM

for the Step Quantity displays.

- Enter the Line from the LOV. Required.

- The following fields are display only:

- Item

displays the code associated with each product, byproduct, or ingredient

listed.

- Type

displays the type of Line associated in the Step as a product, byproduct,

or ingredient.

- Item Qty

displays the Quantity of product, byproduct, or ingredient yielded by the

listed Formula.

- Line UOM

displays the unit of measure for the Item Quantity.

- Save the window

Recipe

Validity Rules

The

Recipe Validity Rules window lets you edit validity rules for a specific

recipe. Use this window to apply global or specific organization rules to

batches, cost management, planning, or technical data when producing the same

product. Validity Rules can be added, updated, or marked for deletion.

Process

loss is based on the standard quantity entered at the validity rule level.

Process loss that is entered at that level overrides the process loss entered

at the routing level. Theoretical Process Loss, Planned Process Loss, Step

Quantity, and Charges fields display at the validity rule level.

Theoretical

Process Loss calculations are also based on the Validity Rule Standard

Quantity. If Planned Process Loss is entered on a validity rule, then its value

overrides process loss defined at any other level in the routing or the recipe.

If a batch is created for a different quantity, then the same rule is applied

to calculate the actual Process Loss. Planned Process Loss is compared to the

Theoretical Process Loss for the Standard Quantity field on a validity rule.

This loss is taken from the Process Loss field for the routing class in order

to compute a factor. The Theoretical Process Loss for the batch quantity is

multiplied by this factor to compute the actual Process Loss for the batch.

Following

are the modifications for the Automatic Step Quantity Calculation, or ASQC:

- If ASQC is not used, then the step quantities displayed

initially are based on the routing, as scaled to the Validity Rule

Standard Quantity. If step quantities are overridden at the recipe level,

then the recipe step quantities are scaled to the Validity Rule Standard

Quantity.

- If ASQC is used, then the Step Quantities displayed are

based on the formula scaled to the Validity Rule Standard Quantity.

Charges

displayed at the validity rule level are based on the step quantities indicated

there. Process Execution, Cost Management, Financials, and Planning

applications use process loss overrides at the validity rule level.

- Navigate to the Recipe Validity Rules window.

- The following fields are display only:

- Formula

displays the formula used in the recipe with its Version and Description.

- Routing

displays the routing used in the recipe with the routing Version

and Description.

- Status

displays the Status of the Validity Rule. This field cannot be higher

than its associated recipe. For example, a Validity Rule cannot be

Approved for General Use until the recipe associated to it is Approved

for General Use.

You can change the

status of recipes or validity rules to On-hold or Obsolete even if they are

used in batches as long all these batches are closed or cancelled.

- Organization

displays the organization that owns this Validity Rule, and the Organization

Description. This must be your Plant or Laboratory. You can enter

and save a new Organization.

- Select Recipe Use as:

- Production

for use in production of products.

- Planning

for use in planning material consumption.

- Costing

for use in establishing costs.

- Technical

for use in establishing technical classes and subclasses.

Required.

- Enter a Product in the Formula for the Validity

Rule. The product Description field displays. Required.

- Enter the Preference number for the Validity

Rule. When more than one formula can be used to produce the same product,

the Preference field is used to show the Validity Rule that must be used

first, second, third, and so forth. Preference defaults to 1. Required.

For example, one

formula can be used to produce between 10 and 150 gallons of a product. Another

formula can be used to produce between 100 and 1000 gallons of the same product.

Since either formula can be used to produce 100 to 150 gallons of material,

the Preference field shows the suggested order of use. Lower numbers indicate a

higher Preference. The number 1 indicates the highest Preference.

- Enter the Standard Quantity of product

made with this Formula. This quantity is only used for product costing.

It does not restrict quantities that can be produced with the Formula.

Standard defaults to the quantity provided in the Formula displayed.

Required.

- UOM is the

unit of measure for the standard quantity. You can enter and save a

different unit of measure. Required.

- Enter the Minimum quantity of product that can

be made using the Formula. Minimum defaults to 1. Required.

- Enter the Maximum quantity of product that can

be made using the Formula. Required.

- Theoretical

displays the theoretical process loss based on the Validity Rule Standard

Quantity.

- Enter the Planned process loss. This overrides

planned process loss entered at the routing level.

- Enter the From date as the date the Validity

Rule becomes effective. The date must be within the effective date for any

routing associated to the recipe. Required.

- Enter To date as the date to stop using the

Validity Rule. This is an optional field and must be left blank if no

expiration date is defined for the Validity Rule.

- The following fields are display only:

- Step

displays the step number associated with the operation displayed.

- Operation

indicates the operation associated to the step. The operation Version

displays.

- Description

indicates a description of the operation.

- Step Quantity and

its UOM indicates the quantity processed by the routing step and

the unit of measure of the step quantity.

- Charges

indicates the total calculated charges for the step.

- Save the window.

Get Flower Effect

Get Flower Effect

No comments:

Post a Comment